A legacy of innovation and environmental leadership in South Africa

Clean power production technologies provider Babcock & Wilcox (B&W) entered the South African market in 1891 to supply boilers to the country’s gold mining industry, at a time when the young company was rapidly expanding to serve new clients throughout the world. By the 1920s, B&W had become a key player in power generation, with a subsidiary supplying coal-fired boilers to Eskom’s first coal fired power station at Colenso in 1927. Since then, many boilers have been supplied in South Africa which have their roots in B&W’s technologies.

B&W reaffirmed its commitment to South Africa by establishing a wholly-owned subsidiary in 2022 and continues to provide new steam generation plants for industries such as sugar, paper and pulp, using biomass, oil and gas as primary fuels.

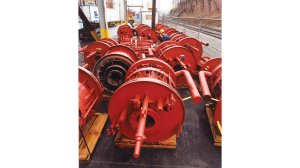

Today, B&W continues to lead in innovation and environmental responsibility. One of its most notable recent achievements in South Africa was a groundbreaking nitrogen oxide (NOx) abatement project at a major petrochemical facility. In response to tightening emissions regulations, B&W supplied 42 of its advanced DRB-XCL low-NOx burners for seven boilers. One of B&W’s most popular burners, more than 3 000 DRB-XCLs have been installed at facilities around the world. The results were remarkable: NOx emissions were reduced from 1 100 mg/Nm³ to just 470 mg/Nm³ – well below the regulatory threshold of 750 mg/Nm³. This project marked one of the first successful NOx reduction efforts in South Africa and further demonstrated B&W’s experience in designing and supplying cutting-edge technology for existing infrastructure.

B&W has also supplied electrostatic precipitators (ESP) equipment to clients in South Africa and continues to support an ongoing major ESP rehabilitation and upgrade at a large coal-fired facility, helping reduce particulate emissions. These efforts are part of a broader commitment to helping South African industries meet increasingly stringent environmental standards. B&W offers a full suite of emissions control technologies, including fabric filters, wet and dry flue gas desulfurisation (FGD) equipment, and dry sorbent injection systems for sulphur dioxide (SO2) reduction to help its clients meet these new regulatory challenges. B&W has broad and deep experience with its entire line of environmental equipment, with more than 1 000 fabric filter installations, more than 750 ESP installations and nearly 400 FGD installations around the world.

B&W also offers advanced coal-to-gas conversion solutions that are helping plant operators transition from coal-fired power generation to cleaner-burning natural gas. These conversions are a strategic option for extending the life of existing assets while significantly reducing emissions, improving operational flexibility, and lowering maintenance costs. B&W’s approach leverages its deep expertise in boiler design and combustion systems to re-engineer coal-fired units for natural gas operation, often without the need for complete boiler replacement. This includes modifications to burners, fuel delivery systems and control technologies to ensure optimal performance and compliance with modern environmental standards.

These projects often result in dramatic reductions in SO2, NOx and particulate matter, aligning with decarbonisation goals and regulatory mandates. In addition to full conversions, B&W also supports dual-fuel capabilities, allowing plants to operate on both coal and gas for greater fuel flexibility, a valuable alternative in regions where energy markets are transitioning or where fuel supply security is a concern.

Service remains a cornerstone of B&W’s value proposition. The company offers upgrades, spare parts, and performance improvements for boiler pressure parts, burners, pulverisers and ash-handling systems. It also provides proprietary diagnostic tools such as EMAT and NOTIS for tube inspection, along with in-house flame scanner and ignitor technologies.

Looking to the future, B&W’s Climate-Bright™ suite of hydrogen and decarbon-isation technologies represents the cutting edge in clean energy generation and emissions control. Its BrightLoop™ chemical looping technology is an exciting innovation that can convert a broad range of feedstocks such as coal, biomass or natural gas into hydrogen or steam while capturing carbon dioxide as a byproduct. B&W currently has four BrightLoop™ facilities under development in the US.

From its historic roots in South Africa’s mining sector, to playing a major role in the development of the country’s modern energy infrastructure, to its current role as a leader in clean energy and emissions control, B&W continues to sustainably and reliably deliver innovative solutions that provide needed power, support economic growth and help to achieve a more prosperous future for the region.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation